- At 07-24-23 10:00:00

- K24 E36

- Zack S

- Read Time: 5 minute read

Unique Engine Swap Adventure: BMW M3 Meets Honda K24

Unique Engine Swap Adventure: BMW M3 Meets Honda K24

Blasphemy? We don't think so....

Engine swaps and car modifications are an art form, a mechanical ballet driven by horsepower and torque. When you've experimented with most of the mainstream swaps and you need to fix its supercharged engine for your slick top M3 Coupe, where do you turn? You take a unique route.

The Engine Swap Adventure Begins

Welcome to the modern era of engine swaps where the sky seems to be the limit. Adapters to match any engine with any transmission and new more robust standalone engine management systems have broadened the horizon of possibilities. Enter the Honda K24A RBB engine, a JDM (Japanese Domestic Market) variant equivalent to the U.S. K24A2 from the Acura TSX, turbocharged and slotted into the heart of an E36 BMW M3.

The K24A engine, part of Honda and Acura's K-series, is known for its robust factory configuration. Even though the K-series engines were not designed for forced induction, enthusiasts have boosted them in stock trim to deliver over 500+whp in various Honda Civic and Acura RSX models. Up the ante with a time tested and nearly standardized built engine and you're looking at a mild 1000+whp.

The purpose of our build was to see 9,000 RPM. The k24 needs only a few refreshed internals to make that happen. The guys over at 4-Piston Racing supplied their ported Honda K20A2 oil pump and Brian crower sent us upgraded valve springs and retainers. We threw in a fresh head gasket, gapped the piston rings for boost, and a set of ARPS. in quick fashon were ready for the high RPMs and high boost that this turbo K-series is destined to see.

Making the Honda - BMW E36 Relationship Work

The main challenge with integrating the K-series into the E36 chassis is resolving the issue of architecture conflict. Remember the K24 is traditionally a transverse mounted engine; therefore, The oil pan, oil pump, and oil pump drive system on the K-series require a relocated steering rack and front subframe. After much consideration, we decided against the dry sump solution, opting to modify the existing subframe.

With the assistance of products from PMC Motorsport, we connected the Honda engine to the stock BMW M3 ZF 5-speed transmission. The list of items includes an adapter plate and a custom flywheel. Next we manufactured custom engine mounts, the combination of which retains the OEM placement of the ZF transmission and reuses the BMW transmission crossmember, mounts, gear shift selector rod, and M3 driveshaft.

The Build, and Driving it to SEMA

With the architectural challenges of the K24 swap in the rearview mirror and our engine bay reconfigured to accommodate the new setup, we were set to tackle the next big task: turbo installation and engine wiring.

Our choice for engine management was the MaxxECU system, we cannot speak highly enough of Maxx. To integrate it, we manufactured a custom wiring harness. Key components in our build included 1000cc injectors and Audi R8 coil, both are high performance options that are readily available and reasonably priced. The turbo, a crucial piece in this power puzzle, was the highly-regarded Garrett G30-770, ideally matched to the 2.4L Honda engine. We were hoping to have a solid torque curve and still breathe up top.

To maximize exhaust flow and turbo performance, we custom-fabricated an equal length v-band exhaust manifold, complete with a full 3-inch downpipe. We retained the existing Active Autowerke midpipe and Dinan muffler, lending the setup an OEM+ appeal, at least while the hood is closed..

The final fitment required a clean and efficient approach. We created TPS adapters and idle control plates, relying on many of our existing 22RPD components to achieve a seamless integration. This included a 22RPD ECU cover, a22RPD standalone harness adapter, and 22RPD intercooler mounts.

Ensuring proper airflow and cooling was a priority. We fabricated a 4-inch intake tube and 3-inch charge piping, deciding to embrace a full pie-cut approach to align with the car's overall style. We selected a large bore Skunk2 throttle body, to which we welded a vibrant Wiggins style clamp. For the intercooler, we chose a Treadstone 1235 unit to keep the intake temperatures in check. Then we converted to full AN lines for the cooling system by welding AN fittings onto our radiator. The factory belt routing was modified to accommodate the swap, and we added an ATI damper for vibration control. Finally, we fabricated a custom tensioner design.

For the three guys who committed themselves to construct this car within an ambitiously self-imposed timeline of only days, then dared to venture on a 2200-mile round trip in their fresh creation, the journey was nothing short of epic. This endeavor stood as a vivid testament to their collective determination, resourcefulness, and shared passion for automotive innovation. More than a test of resilience, it was an unforgettable, once-in-a-lifetime adventure.

Reaping the Benefits of a K24 Swap: The Power, Performance, and Balance

Throughout this unique engine swapping journey, we've experienced firsthand the extraordinary benefits of the Honda K24 engine. A phrase you might see often, #Kswaptheworld, is much more than just a hashtag it's an acknowledgment of the engine's remarkable potential, inspiring enthusiasts all around the world to breathe new life into their vehicles with a K-series transplant.

By employing the K24, we've created a refreshed unique driving experience, with an incredibly linear throttle response that pulls to 9000 rpm. There's no unexpected surge of power, just smooth acceleration as the turbo seamlessly spools up. This smooth and linear power delivery translates into effortless speed the car just GOES! Furthermore, the K24's higher rev limit dramatically reduces gear shifts, allowing a 60-130 roll with just 2 gear changes instead of 3. This, coupled with the significant weight reduction achieved through the 4-cylinder swap, puts our M3 on par with other E36s boasting far greater numbers.

A major shift with this setup is the move towards a near front mid-engine design. The K24 is positioned further back in the bay, which drastically improves the vehicle's sharpness, balance, and handling. This change in configuration brings a new level of agility and responsiveness, adding another dimension to the driving experience.

Despite all these performance benefits, the K24 swap doesn't break the bank. The high volume of Honda parts in the aftermarket makes this swap a cost-effective solution, particularly when compared to the equivalent BMW parts.

The result is the K24 swap brings power, performance, improved handling, a superior driving experience, and cost-effectiveness. It might seem a little unconventional, perhaps even blasphemous to some, but the benefits speak for themselves. This engine swap truly challenges the norms and pushes the boundaries of what's possible with an e36. After all, isn't that what being a car enthusiast is all about?

On the Horizon for 22RPD

Our clutch has been struggling to harness the torque and abuse we have been putting through it and we've experienced some slip. This led to a few rev limit slams, resulting in an intake valve contact with the piston on the #1 cylinder. A compression loss from a bent valve face means the motor is due for a teardown.

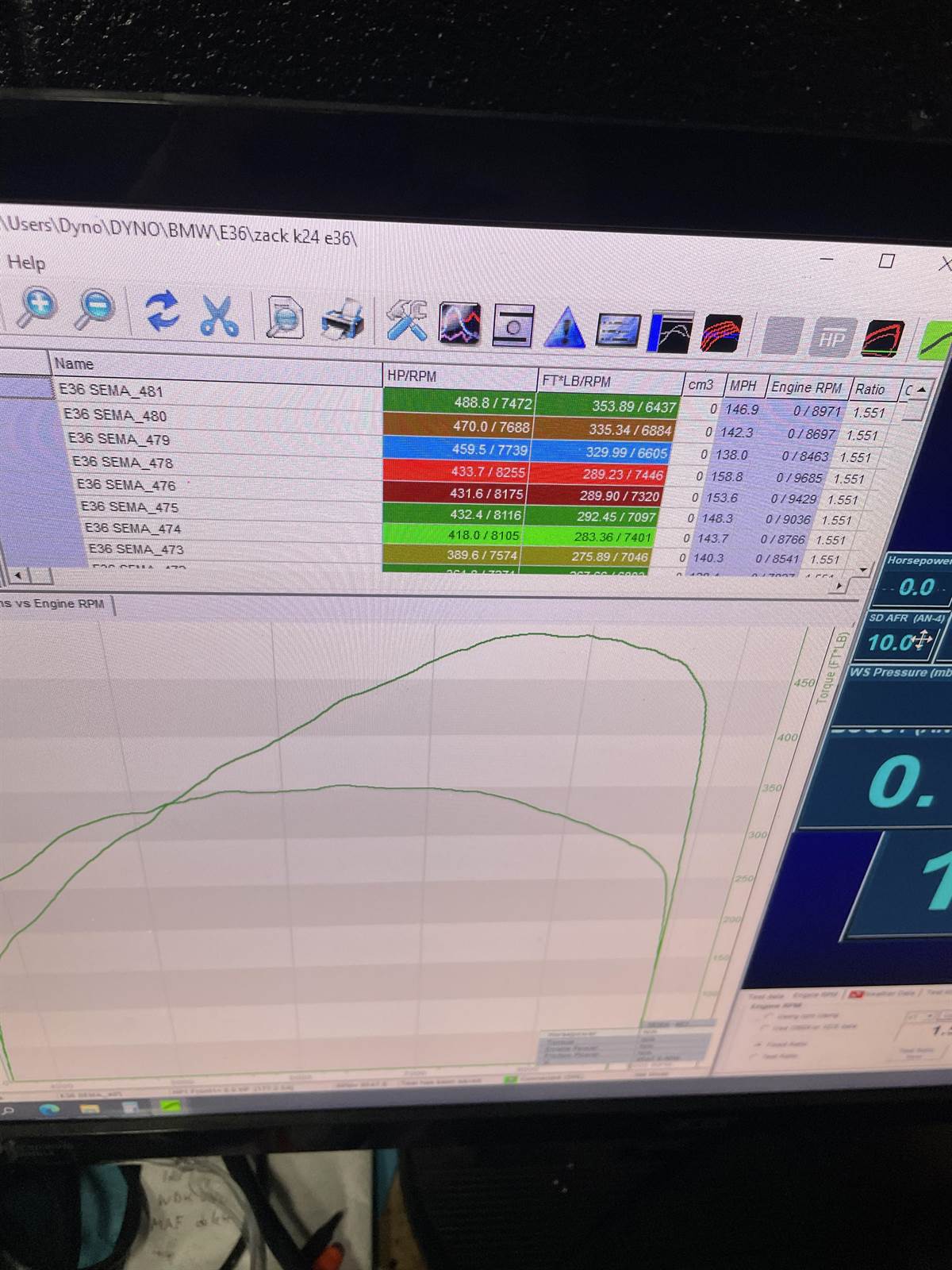

We're currently exploring the market for potential 22RPD parts to facilitate this swap for our customers. Follow us closely as we aim for the 700whp mark with the help of ethanol, and who knows how far we'll push it from there.

The exciting journey of this unique engine swap continues to evolve, pushing the boundaries of what's possible and redefining what it means to be a unicorn car.

Shout out to everyone involved in the build, the trip and the documentation. Cole, Jimmy, Ian, and Jacques.