- At 02-17-25 09:45:00

- Product Releases

- Zack S

- Read Time: 3 minute read

The Future of N52 Trumpets

In our previous blogs, we've shared the journey of developing innovative intake solutions for the BMW N52 engine. In the "N52 Velocity Stacks Update and BETA2 Release Sign-Up," we discussed the progress and testing phases of our velocity stacks, highlighting their performance in various racing disciplines. Similarly, in "The Future of NA N52: No Throttle Body [Bonus: Beta Testing Sign-up]," we introduced a throttle-less intake design that leverages the Valvetronic system, aiming to eliminate restrictions and enhance engine breathing.

Today, we want to address the challenges we've encountered in manufacturing these advanced components. Initially, we adopted an agile production approach using 3D printing, exploring various manufacturers, materials, and production methods. Despite the functionality of the products, we found that this method did not meet our standards for a final, non-beta release. The complexity of the designs, especially with the intricate trumpet shapes, presented significant challenges in 3D printing. The viability of a final filtered design does not seem possible with the technology's current limitations, at least when balanced across producibility, lifespan, and cost. This is why we have had to push our timelines quality remains our highest priority, and we refuse to compromise on delivering a final product that doesn't meet our standards.

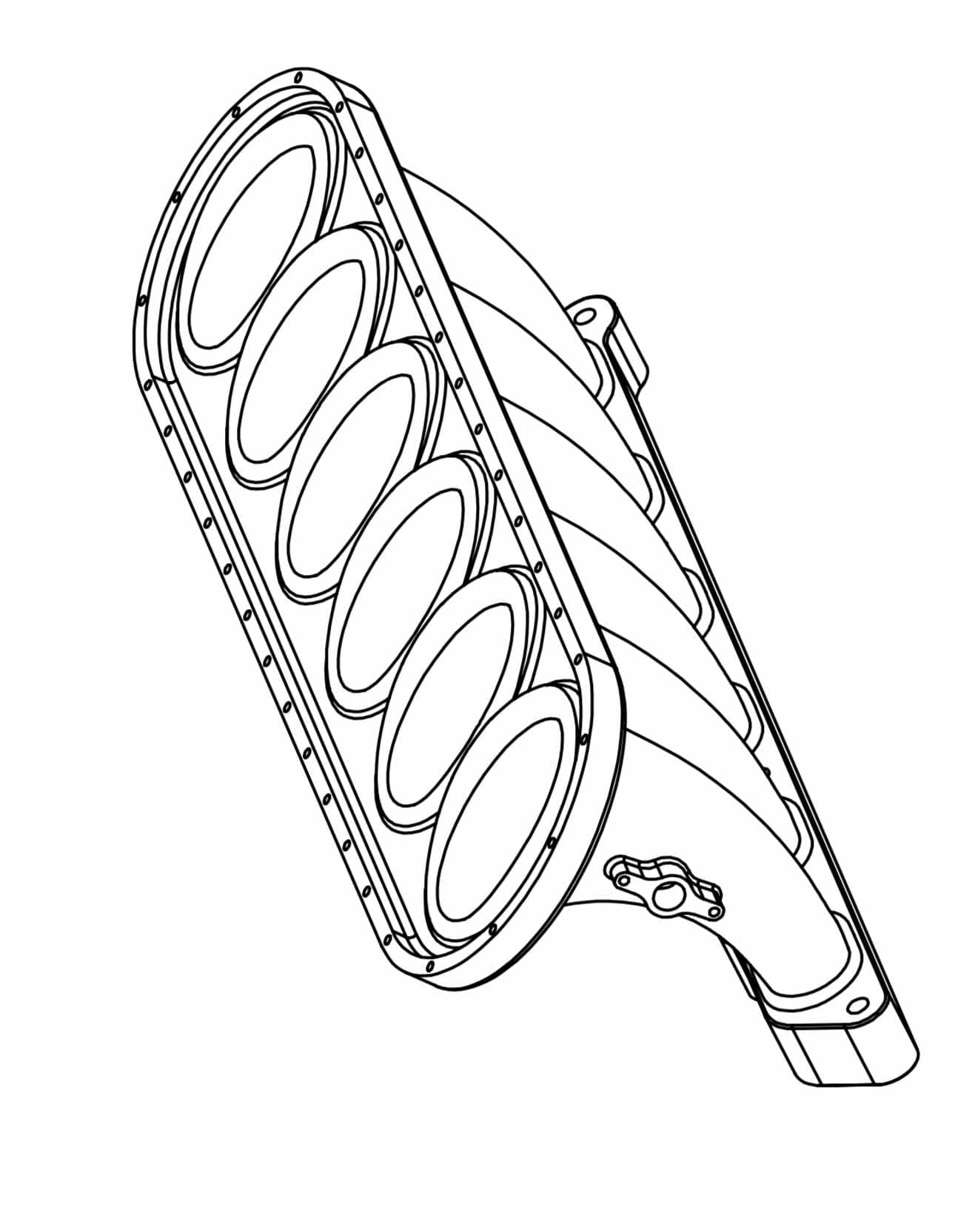

Consequently, we evaluated alternative manufacturing methods, such as injection molding and aluminum casting. Each presented its own set of challenges, but after thorough consideration, we've determined that designing a modular cast aluminum manifold is the optimal path forward. Aluminum casting, on the other hand, provides the durability, heat resistance, and consistency necessary for a professional-grade product. This process allows us to create high-performance parts with precision while maintaining the structural integrity required for motorsport and daily use. Additionally, casting offers design flexibility, making it ideal for a modular system that can support different applications.

This approach promises a complete and producible product, with casting conducted in the USA and final machining at our facility in Renton, WA. While this method is more costly, it aligns with our commitment to quality and performance. However, the viability of this endeavor is contingent upon market demand. To support a professional product that aligns with our company ideals, we need sufficient volume. If the interest does not meet the necessary threshold, we may have to discontinue the trumpet product as half measures don't benefit anyone.

On a more exciting note, the concept of a modular manifold opens up a plethora of possibilities. "Modular" means customizable configurations such as:

- Party mode

- Filtered panel

- Filtered wedge inlet with throttle body flange

- Filtered stock location center feed

- Intercooled intake for boosted applications

- Nitrous bungs

- Direct port meth

We are committed to making this project open-source. We will provide design templates for DIY printing plenums and additional components, allowing users to modify and customize their setups as needed while budling on the optimized runners we have. Whether it's adapting the intake for specific racing applications, designing custom air filtration solutions, or creating specialized velocity stacks, enthusiasts will have the tools to experiment and innovate within our foundational design. Our goal is to foster a community-driven development model where users can share ideas and contribute to the evolution of this platform.

These configurations are designed to be open-source, allowing for user-implemented applications. All configurations are centered around the optimized trumpet shape and length, which have demonstrated significant power gains. This adaptability makes the product applicable to a wide range of vehicles, with no exclusions.

Imagine a water-cooled plate that seamlessly integrates with our supercharger kit, connected by only a single 3" long coupler, enhancing both efficiency and aesthetics. Envision turbo applications with a flow-optimized wedge inlet, or extreme ported heads with CNC port-matched intakes tailored to fit like the high end Honda motors which are doing 300whp N/A out of a 2.4l, could that mean we see 375whp n52's?

We are currently researching and optimizing this product and seek to gauge interest to determine its feasibility. Here are some preliminary kit setups and potential costs: (To be updated in the coming weeks)

- Base party mode kit: $

- Base panel filtered kit: $

- Base wedge inlet kit: $

- Base center feed kit: $

- Water intercooled kit: $

We acknowledge that these options are not the most affordable, but our goal is to offer the best-performing, highest-quality products, proudly made in the USA. While this may not resonate with everyone, we take pride in our craftsmanship. Outsourcing production overseas would compromise our control over quality and performance, which is unacceptable to us.

We invite you to share your thoughts and interest in this modular manifold concept. Your feedback is invaluable as we strive to deliver products that meet your expectations and uphold our standards of excellence.

Update - May 28, 2025

Several weeks ago, we ran a poll to gauge interest in a production version of our N52 trumpets and the response was clear: while there was enthusiasm for the product, the estimated pricing for a cast aluminum version was simply too high for most.

As a result, we've made the call to shift production to an injection-molded design, similar to the construction of the factory intake. This allows us to:

-

Dramatically lower the final cost to the customer

-

Maintain the performance and fitment gains we've proven in testing

-

Support future variants like filtered stacks, modular velocity lengths, or boosted applications

Tooling for the injection-molded version is already underway. We'll share timelines and preorder info soon thank you to everyone who voted and helped guide this decision.

- Team 22RPD