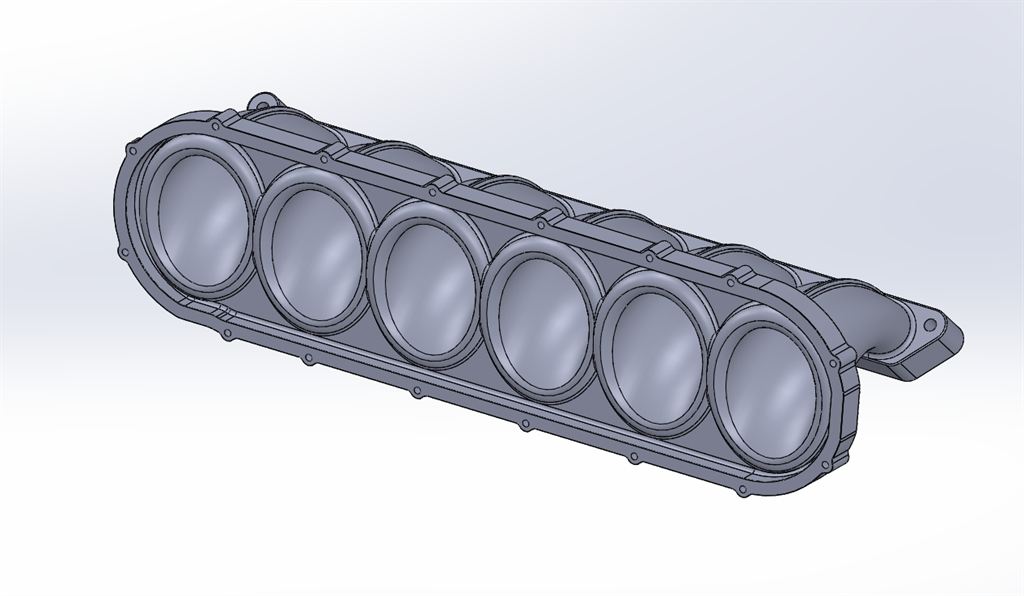

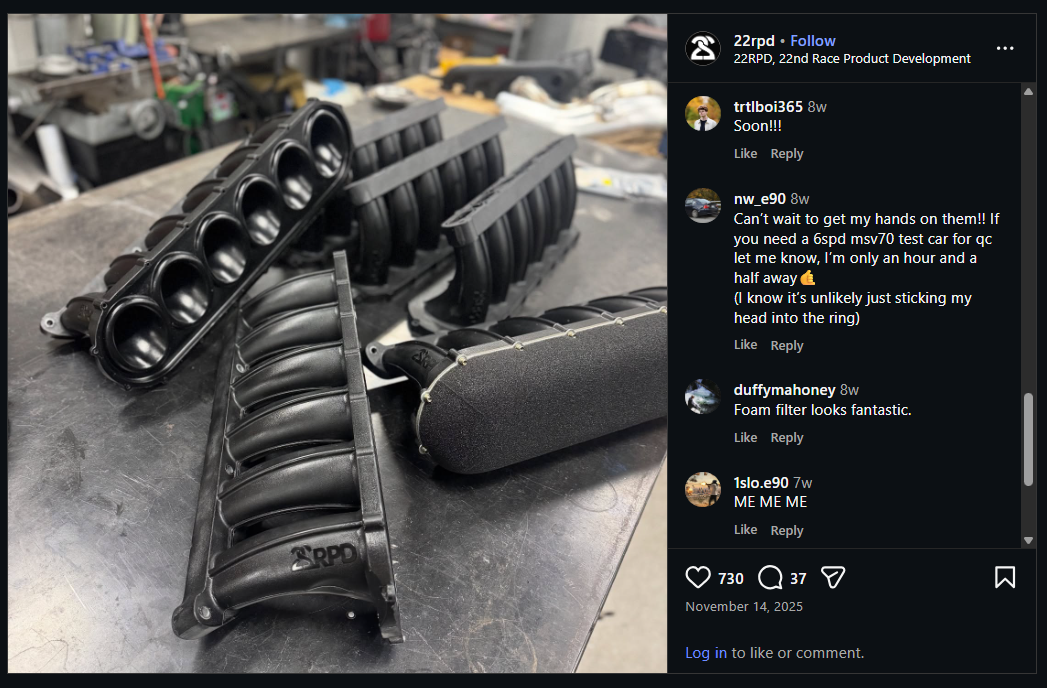

Initial Samples and Inspection

On November 14th, 2025, we shared QC photos of the first injection-molded N52 velocity stacks after receiving initial sample units from our manufacturing partner in Germany. At that stage, we were encouraged by the overall execution and felt confident we were close to release.

During final inspection and test fitting, however, we identified shrinkage in the injection mold that materially affected the final geometry of the parts. In simple terms, the shrinkage was significant enough that the velocity stacks no longer fit the intake ports correctly. This was not a case of something that could be worked around or selectively adjusted. The parts physically did not fit as required, which makes them impossible for us to sell.

Correcting this properly requires a mold revision.

Shrinkage Root Cause

It is worth noting that shrink compensation is the responsibility of the manufacturer and was accounted for during their mold design. However, the complex geometry of this part, combined with post-molding annealing operations, makes shrinkage behavior difficult to model perfectly. In this case, the shrinkage calculation was incorrect.

Now, with a real-world molded and annealed part in hand, the manufacturer can calculate shrinkage with significantly greater accuracy across the entire geometry.

Why a Mold Revision Creates a V2 Opportunity

Because the mold must be remade to address shrinkage properly, we are afforded a rare and valuable opportunity to step back and intentionally improve the part rather than simply correcting a single issue. Injection-molded parts rarely get meaningful iteration once tooling is cut, and in reality, you do not fully understand what needs refinement until you can physically inspect and test the first parts after the very expensive mold is completed.

Having the chance to revise the mold with real-world feedback is a significant advantage. This is the benefit of doing real product development instead of rushing parts to market. The result is a more refined design that not only solves the original problem, but advances the overall quality, fitment, and finish, fully earning its place as a 22RPD part.

Surface Finish and Edge Refinements

Over the past several weeks, we have worked closely with our manufacturing partner through the mold revision process. These discussions allowed both teams to align more deeply on the specifics of the molding process, material behavior, and the constraints unique to this type of part.

While our original design intent remains unchanged, the combination of their manufacturing experience and a real-world molded sample allowed us to identify small, optional refinements to surface finish and edge definition. These updates are not required for function, but they improve the overall execution of the part. While they do introduce additional manufacturing cost, we are comfortable making that investment in exchange for higher execution quality and long-term confidence in the final product.

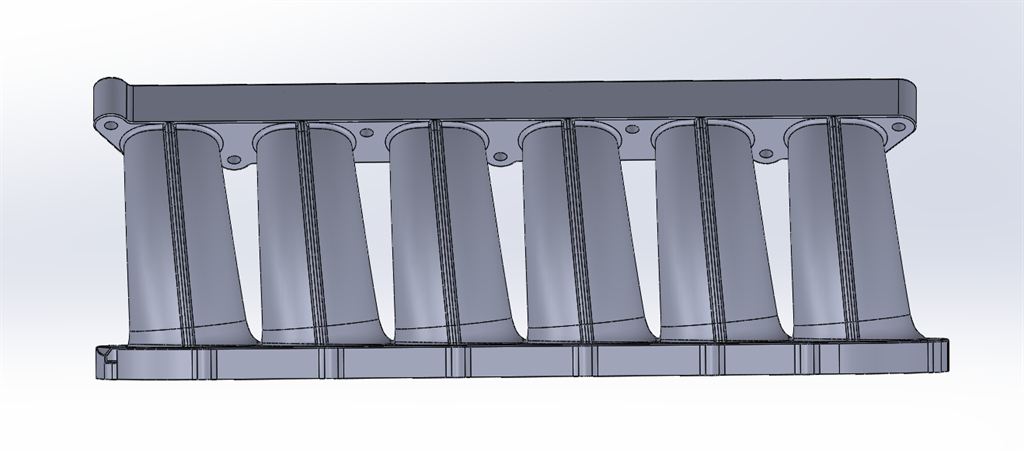

Runner Geometry and Performance Optimization

In parallel, we made a deliberate design adjustment to the runner placement. With the mold being revised, this became a clean-sheet opportunity rather than a minor tweak. The runners have been revised with a slight angle, improving overall fitment and providing better clearance throughout the installation.

While subtle, these changes compound into a cleaner, more consistent install and a more robust final design without compromising performance. Even in the smallest details, the V2 design is simply better.

As part of this clean-sheet revision, we were also able to slightly optimize the runner profile and taper, further improving the theoretical airflow characteristics of the part. This is a small gain and not something that was required for performance, but it is exactly the type of refinement that becomes practical when a tool is already being revised and real-world parts exist. The original design intent and performance targets remain unchanged.

What This Means for Existing Orders

Because of these changes, we are formally moving forward with a V2 version of the N52 velocity stacks. All existing orders will automatically receive this updated version at no additional cost.

We understand that delays are frustrating, and we genuinely appreciate the patience and trust shown by everyone who ordered early. Our philosophy is straightforward. If we are going to put our name on a part, it needs to fit correctly, perform as intended, and meet our standards. Sometimes that means slowing down, fixing the root issue, and using the opportunity to make the product better than originally planned.

Timeline and Next Steps

We have been advised by our manufacturing partner that the revised mold design is expected to be completed in approximately two weeks. Pending our approval, they will immediately move forward with manufacturing the updated tool.

We will continue to share updates as the process progresses and look forward to delivering a final product that reflects the level of care and engineering behind it.