- At 12-04-20 05:00:00

- Product Releases

- Zack S

- Read Time: 3 minute read

22RPD Fuel Pump Hangar Design

In 2019 we started using AEM's 400LPh fuel pump. This is an upgraded version of the legendary Bosch 044 pump. We have liked them so much we decided to design a plug and play solution for the e36 platform. In this article we will discuss what makes this pump exceptional and we will detail our new solution for the pump in our e36.

Let's start with the E36's fuel demands:

Now obviously all of these figures are hugely dependent on the turbo, cams, displacement, and so fourth. Regardless they are a rough number and will be useful for the remainder of this discussion.

On pump gas an E36 uses roughly:

- 1 LPH of fuel at idle

- Wide open throttle, at 7000rpm, NA 70 LPH of fuel

- Turbo running 20 pounds of boost at 7000rpm, 215LPH of fuel @ 71 psi fuel pressure

And on E85:

- 1.4 LPH of fuel at idle

- Wide open throttle, at 7000rpm, NA 95LPH of fuel

- Turbo running 20 pounds of boost at 7000rpm, 300lph of fuel @ 71 psi fuel pressure

- A turbo running 30lb of boost at 7000rpm, 350lph @ 81 psi fuel pressure

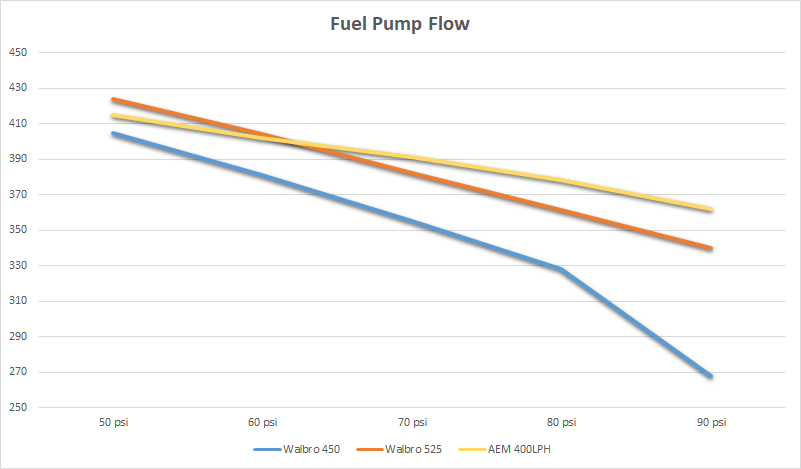

By knowing these demands you can begin to estimate how much pump you will need. In the next two charts we have graphed the two most popular boosted fuel pumps and the pump we designed this new hangar for. The x-axis, running horizontally, is the fuel pressure, while the vertical column, y-axis, is the pump flow. Fuel pressure rises 1:1 with boost (in most circumstances); therefore, 10 psi of boost paired with stock 51 psi fuel pressure means 61psi of fuel pressure.

In the figure below, the latest offering from Walbro, starts out with an advantage to the AEM pump, but suffers substantially on the top end. Meanwhile the original Walbro 450 suffers significantly everywhere. In use we do not need nearly that much fuel at idle, checkout the stats above and see that were using just a fraction of what the pump is producing.

(Fuel Pump Flow: LPH Fuel flow VS PSI Fuel Pressure)

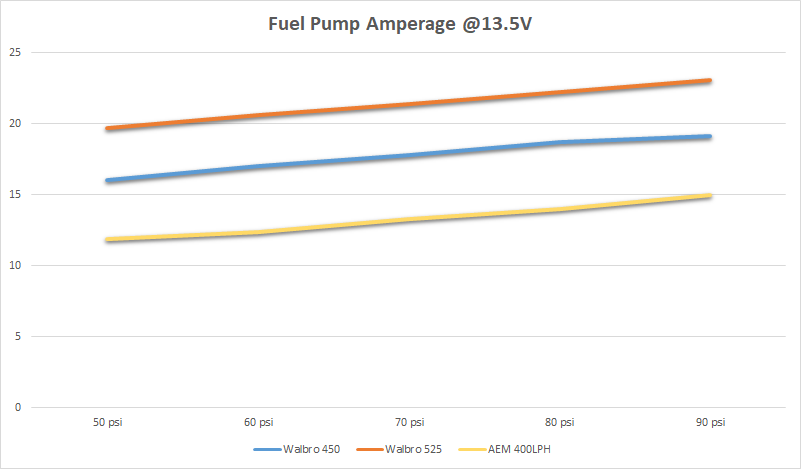

One of the biggest Differences, and the reason we really like these pumps is the amperage draw!

Look how the highest flowing AEM pump maintains less than 15A draw! This is a significant reduction! The Walbro uses 50% more amperage. This may not seem significant but when you are running two pumps and a stock 70A e36 alternator, 44.5A from the twin Walbros is absolutely overdrawing the system. Running two of the AEM pumps would only be using 28A! Most of this efficiency comes purely from the size of the pump, the motor and impeller. You can nearly run the AEM on stock pump wiring! With its large pump size, roller vane impeller, and ceramic end plate, the AEM is expected to have an extremely robust lifespan compared to the walbro.

We decided to disassemble one of each of the pumps. An 044 style pump uses a much larger motor versus the Walbro style. Comparing weight alone its nearly 50% bigger at 8.8oz versus 4.6oz from the walbro. The business card is out of focus but gives you a size reference of each.

AEM armature on the left, Walbro on the right.

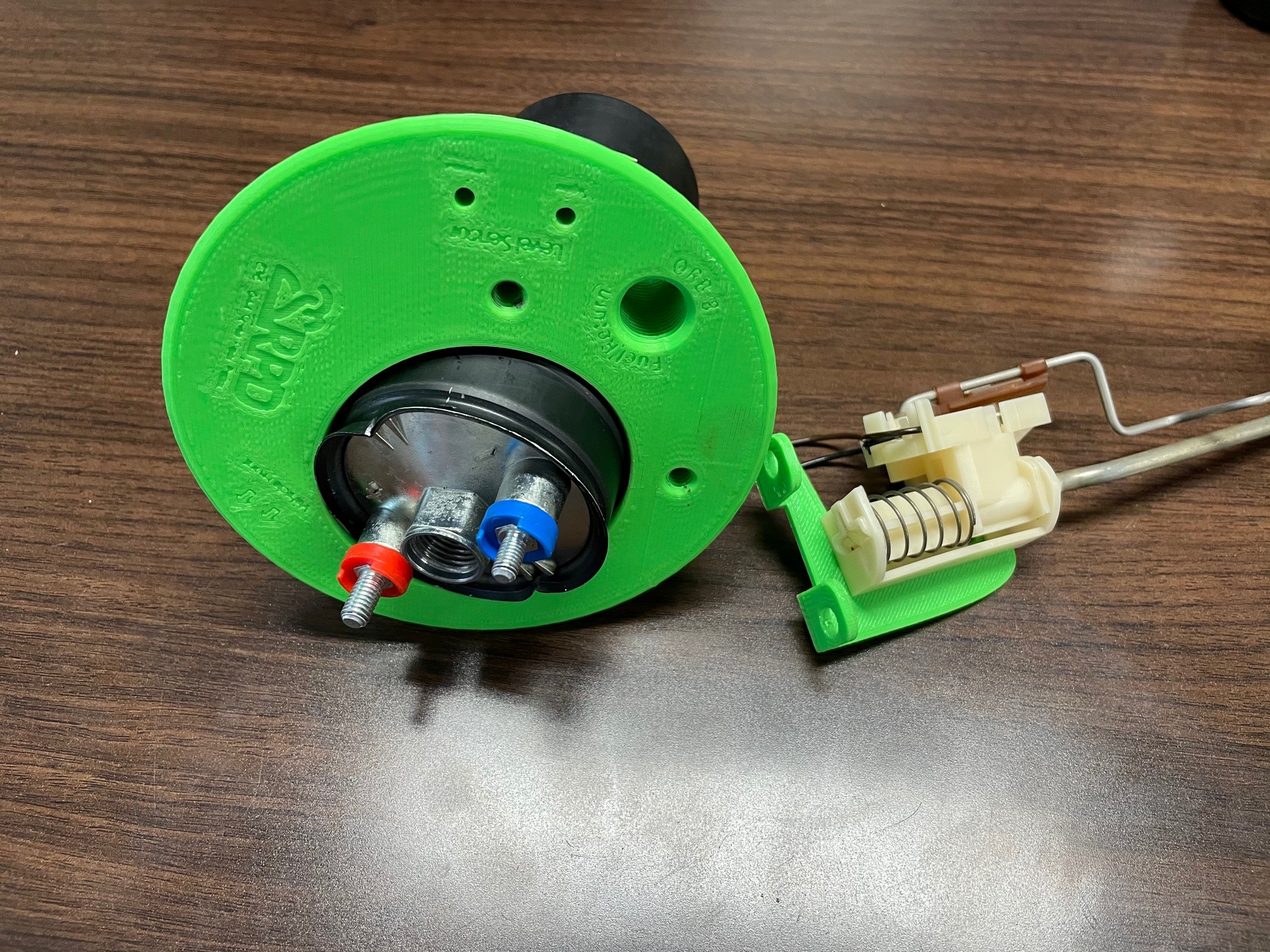

Next lets take a look at the new pump hangar design.

We 3d printed the whole product to do a design review. We wanted this hangar to be the best available product it can be but also be the easiest to install.

The pump slides in over an o-ring seal, and is bolted into place by a stainless bracket. The factory level sensor is maintained, simply snap it onto a laser cut stainless plate and install it with two m6 screws onto the bottom of the hangar.

Each hangar comes with an optional 1/2" ORB port which can be used to convert to divorced fuel returns, eliminating the factory syphon pump issues.

Re-use the factory rubber tank seal and slide in our new hangar. All oem fuel strainers ("Fuel socks") are a direct fit for this system.

Final Notes

A single AEM will flow enough for 1000+WHP on non-ethanol blends, and enough for roughly 750WHP on ethanol blends. For people looking to exercise 1000 whp or greater on ethanol blends we are offering a twin-pump setup.

Final details worth noting:

- This fuel hangar setup retains factory level sensor mount

- There is an upgraded fuel return port system designed in on this unit. Details for how to use it are detailed in your install manual

- All materials on the unit are anodized 6061-t6 aluminum, or 304 stainless steel for extreme life/durability.

- Electrical connectors are sealed with Nylon 6/6 bushings which are completely fuel safe.

- All electrical connectors, and hardware is included.

- It is anticipated that you will reuse your factory fuel tank seal

All final units are to be fully cnc machined, hard anodized, and laser etched. Stay tuned for unit finalization and pricing!