- At 02-05-25 09:45:00

- Product Releases

- Zack S

- Read Time: 1 minute read

n52

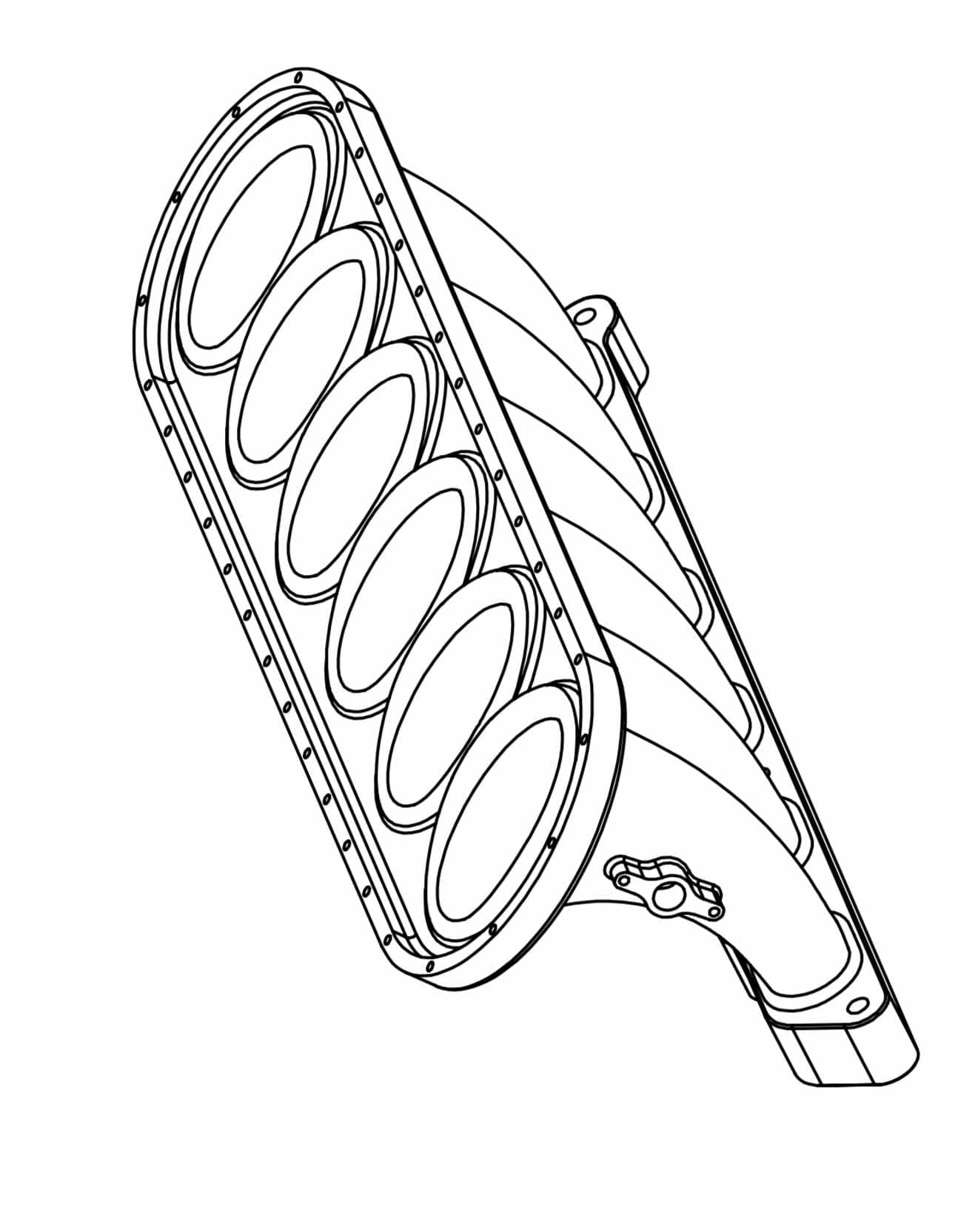

In our previous blogs, we've shared the journey of developing innovative intake solutions for the BMW N52 engine. In the "N52 Velocity Stacks Update and BETA2 Release Sign-Up," we discussed the progress and testing phases of our velocity stacks, highlighting their performance in various racing disciplines. Similarly, in "The Future of NA N52: No Throttle Body [Bonus: Beta Testing Sign-up]," we introduced a throttle-less intake design that leverages the Valvetronic system, aiming to eliminate restrictions and enhance engine breathing.

Today, we want to address the challenges we've encountered in manufacturing these advanced components. Initially, we adopted an agile production approach using 3D printing, exploring various manufacturers, materials, and production methods. Despite the functionality of the products, we found that this method did not meet our standards for a final, non-beta release. The complexity of the designs, especially with the intricate trumpet shapes, presented significant challenges in 3D printing. The viability of a final filtered design does not seem possible with the technology's current limitations, at least when balanced across producibility, lifespan, and cost. This is why we have had to push our timelinesâ€â€quality remains our highest priority, and we refuse to compromise on delivering a product that doesn't meet our standards.

Consequently, we evaluated alternative manufacturing methods, such as injection molding and aluminum casting. Each presented its own set of challenges, but after thorough consideration, we've determined that designing a modular cast aluminum manifold is the optimal path forward. Aluminum casting, on the other hand, provides the durability, heat resistance, and consistency necessary for a professional-grade product. This process allows us to create high-performance parts with precision while maintaining the structural integrity required for motorsport and daily use. Additionally, casting offers design flexibility, making it ideal for a modular system that can support different applications.